Precision and efficiency in battery production thanks to Laser technology

Batteries have become incredibly important over the past two decades. From mobile communication devices such as smartphones to electro mobility, batteries and rechargeable batteries now play a key role in many areas of life. And production must do justice to this importance. Laser systems enable extremely precise material processing, which is crucial in battery production.

Solve the challenges in battery production with us

Overall, battery manufacturing with Laser offers exciting possibilities for battery production that can improve the performance and efficiency of batteries. Laser can cut, engrave and weld materials such as lithium, graphite and electrolytes with micrometer precision. This results in battery components of the highest quality and significantly improves battery performance.

Thus, Laser systems in manufacturing are one way of ensuring that this technology can develop its full potential. Batteries can be produced with higher performance and lower costs using Laser manufacturing methods.

There are four main challenges in battery production with Laser systems:

Material

Not all materials used in batteries are suitable for processing with Lasern.

Temperature

The use of Lasern can generate a considerable amount of heat, which can lead to problems such as deformation or melting of the material.

Purity

The Lasertechnology can generate impurities or release existing impurities, which can jeopardize material purity.

Cost reduction

The purchase and maintenance of Lasercomponents for battery production can be expensive. We can help you choose the right products

How does Innotech Laser support you in battery cell production?

Selecting the right Lasercomponents plays a crucial role in the success and efficiency of the battery manufacturing process. The experienced experts at Innotech Laser will skillfully support you in the selection of Lasercomponents for battery production so that you can solve your challenges in a targeted manner.

Advantages:

- First-class advice on the selection of Laser for battery production

- Years of experience in advising on Laser manufacturing systems

- Customized solutions thanks to a wide range of products

- High quality Laserproducts for process improvement

- Technical support and maintenance of our products

"Selecting the right Lasercomponents is crucial to the success and competitiveness of battery manufacturers. We are happy to help you select suitable Laserproducts for battery production."

Maximilian Abeln, Innotech Laser GmbH

Typical applications in battery production

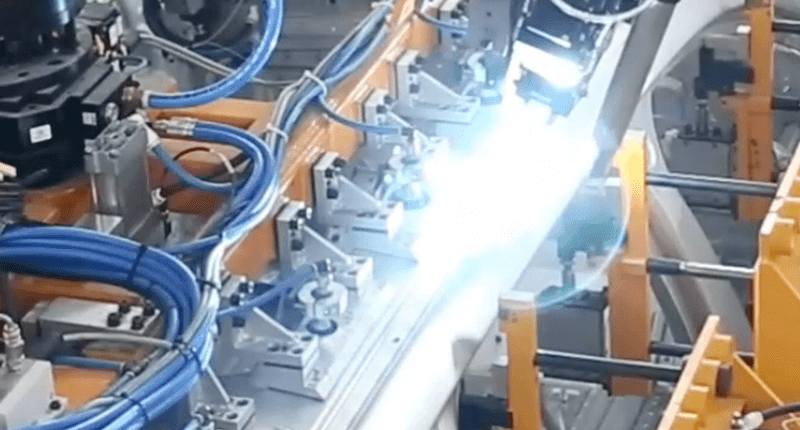

Welding of battery cells

Laserwelding is used to join battery cells and components together. This results in reliable and tight weld seams that ensure battery integrity.

Most selected Lasersource for welding battery cells

Raycus ABP fiber Laser RFL-ABP-4000/2000

Cutting of electrode materials

Laser are used to create precise cuts in electrode materials such as lithium-ion battery foils, anodes and cathodes. This enables the production of battery electrodes with precisely defined sizes and shapes.

Most frequently selected configuration for cutting electrode materials

Huaray Nanoseconds DPSS Laser Pine 532-30

Galvo scanner innoSCAN II-12

Laser Optics F-Theta 532 nm

Labeling and marking batteries

Laser are used for engraving serial numbers, QR codes and other markings on batteries and battery components. This enables the traceability and identification of batteries.

Most frequently selected configuration for engraving and marking

MOPA fiberlaser

RFL-P30MX

Galvo scanner innoSCAN II-10

Laser Optics F-Theta 1064 nm

Further applications

Glass laser

The laser treatment of glass surfaces is an application for which Laser systems are made: They create patterns, smooth or clean the surface as required.

More about glass laser treatment

Laser welding

Laser welding enables the production of high-quality welded joints with low distortion.

Laser marking

Laser labeling systems are used to label, personalize, track or apply information to products.

More about Laser markingLet us advise you and test for yourself

If you have any questions, need a quote or would like to test a configuration in our technical center, please send us an e-mail or simply give us a call. We will answer you as quickly as possible.

Contact us

Address

Innotech Laser GmbH

Giesenheide 31

40724 Hilden

Germany

Office hours

Monday to Thursday

08:30 am to 5:00 pm

Friday

08:30 am to 4:00 pm