Laser Cleaning continues to gain ground

Non-contact, extremely fast, uniform and non-destructive: no wonder the future of Laser cleaning looks so promising. The Laser cleaning technology offers numerous application possibilities in various industries and is very much in fashion.

Trends and developments influencing the future of Laser cleaning

Overall, it can be said that Laser cleaning technology will play an important role in surface cleaning and preparation in various industries in the future.

Ongoing research and development in this area will help to further improve the efficiency and versatility of the technology.

Efficiency

The Laser cleaning technology is constantly being improved to work even faster and more efficiently.

Versatility

Laser cleaning has a wide range of applications, e.g. in facade cleaning, the automotive industry and medical technology.

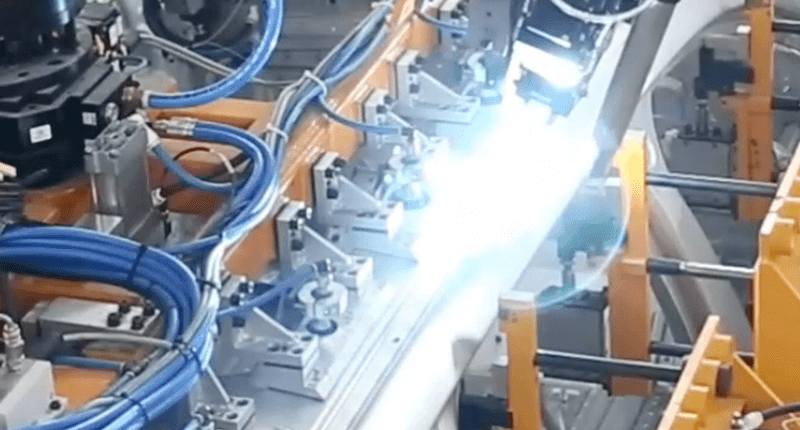

Automation

The integration of Laser cleaning systems into automated production lines will increase.

Cost reduction

The increasing development and spread of Laser cleaning technology could reduce the costs of equipment and operation.

How does Innotech Laser support you with Laser cleaning?

Laser cleaning is a difficult process that has to take many factors into account, depending on the material and dimensions. We use all our expertise to help you put together the right Laser system components to achieve your goals.

Innotech Laser not only helps you to select Laser components for Laser cleaning, but also provides the Laser lab as an environment for testing various methods and components for their suitability for your process.

Advantages:

- First-class advice on the selection of Laser cleaning products, including test environment

- Experience in Laser cleaning thanks to increasing customer projects

- Selection from a portfolio of high-quality Laser products for process optimization

- Technical support and maintenance of our products

"Thanks to various customer projects in the field of Laser cleaning, Innotech Laser can provide you with the best advice and support when selecting Laser components."

Oliver Döpfer, Innotech Laser GmbH

Typical applications in Laser cleaning

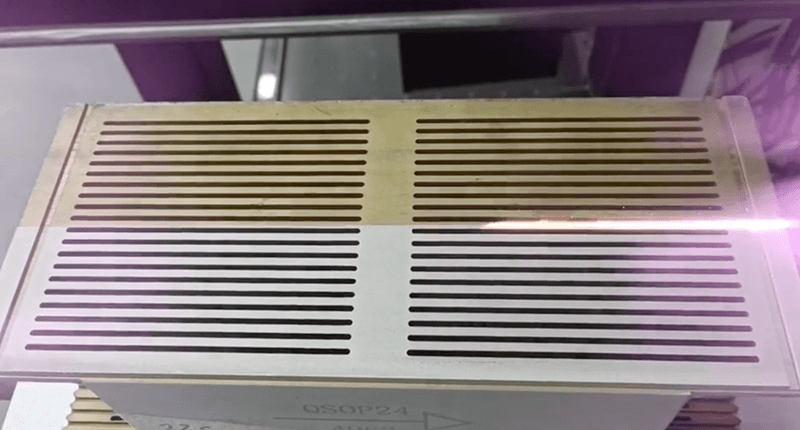

Remove coatings

The removal of coatings such as paints, metals or polymers with Lasercleaning systems is one of the most common applications of this technology, as it can precisely and efficiently remove contaminants from surfaces.

Most frequently selected configuration for removing coatings

Raycus High-Power Pulsed RFL-P500H

Galvo scanner innoSCAN II-20

Laser Optics F-Theta 1064 nm

Rust removal from metals

Rust removal from metals with Lasercleaning systems is an extremely efficient and precise method for removing rust and other contaminants from metal surfaces such as oils or greases.

Most frequently selected configuration for derusting and degreasing surfaces

Raycus High-Power Pulsed RFL-P500H

Galvo scanner innoSCAN II-20

Laser Optics F-Theta 1064 nm

Surface finishing with Laser cleaning systems

Surface finishing with Laser cleaning systems is an advanced method of improving surface quality and functionality as well as enhancing the appearance.

Most frequently selected configuration for surface finishing

Raycus High-Power Pulsed RFL-P500H

Galvo scanner innoSCAN II-20

Laser Optics F-Theta 1064 nm

Let us advise you and test for yourself

If you have any questions, need a quote or would like to test a configuration in our technical center, please send us an e-mail or simply give us a call. We will answer you as quickly as possible.

Contact us

Address

Innotech Laser GmbH

Giesenheide 31

40724 Hilden

Germany

Office hours

Monday to Thursday

08:30 am to 5:00 pm

Friday

08:30 am to 4:00 pm

Further applications

Laser welding

Laser welding enables the production of high-quality welded joints with low distortion.

Laser cutting

Laser systems are tools that are low-wear and versatile. They are therefore used in almost all industries for cutting materials, hard or soft.

More about cutting Laser

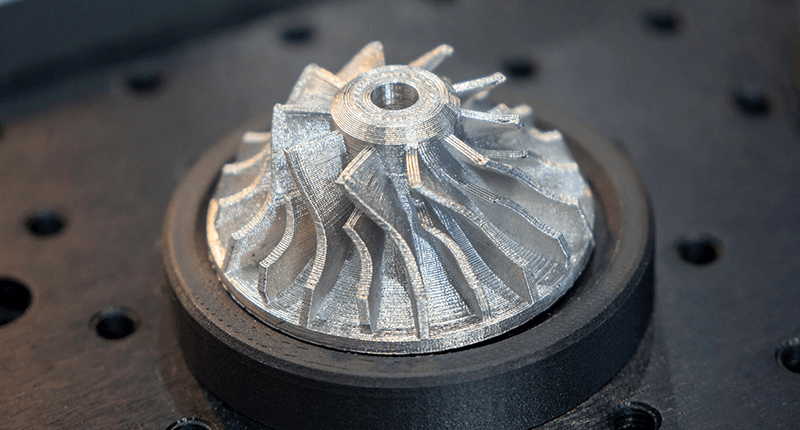

Laser 3D printing

Laser Additive manufacturing, or Laser-based 3D printing, is a revolutionary manufacturing technology for creating prototypes and sample parts.