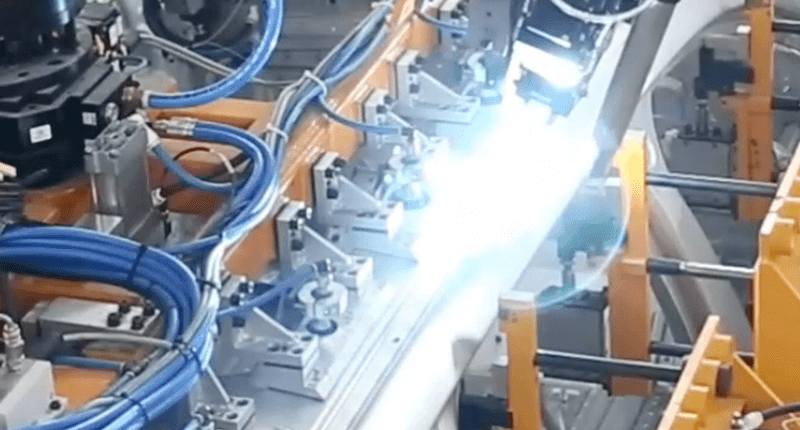

Unbeatable welding precision with the help of Laser technology

Laser welding is a welding process in which a Laser beam is used to weld workpieces together. The Laser generates high temperatures at certain points to fuse the materials together. The resulting weld seam is very precise and uniform.

This process offers many advantages and is widely used in various industries, including the manufacturing and automotive industries.

Advantages of Laser welding

Laser welding enables the production of high-quality welded joints with low distortion. It is an important technology in modern production, especially when welding metals and plastics.

Even for sensitive or difficult materials such as cast iron or stainless steel, you can work with us to find exactly the right combination of Laser system components for your application.

Precision

Laser welding enables extremely precise weld seams, as the Laser beam is very focused and controllable. This results in less distortion and a higher welding quality.

Temperature

The low heat input due to the fast process prevents the risk of distortion and material changes

Speed

A fast machining process enables welding in record time. This is particularly advantageous in series production.

Versatility

Welding Laseris particularly suitable for joining metals and plastics.

How does Innotech Laser support you with Laser welding?

Selecting the right Laser components plays a crucial role in the success and efficiency of Laser welding. With the help of our experts' advice and careful selection of the right Laser components, you will get a Laser welding system that meets your requirements in the long term.

Here are some key aspects where Innotech Laser GmbH can assist in the selection of Laser components for welding metals or plastics.

Advantages:

- First-class advice on selecting the right Laser source and welding heads

- Tailor-made solutions thanks to a large selection of components from well-known manufacturers

- Experience thanks to a large customer base in Laser welding

- Technical support and maintenance of our products

"Our products represent a high-quality and cost-effective alternative for our customers. We look forward to hearing from you and you too can benefit from our experience in welding various materials at Laser."

Oliver Döpfer, Innotech Laser GmbH

Typical applications for welding with Laser

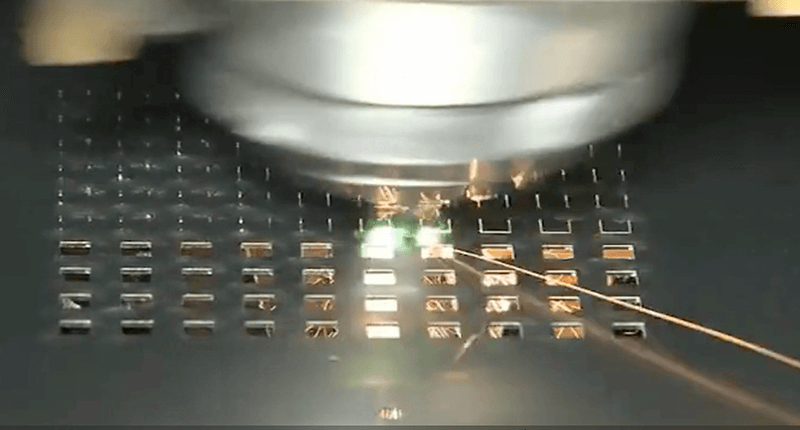

Laser welding of electronic components

Laser welding is used in the electronics industry to connect tiny components such as microchips, sensors and contacts.

Most frequently selected configuration for welding electronic components Laser

Raycus QCW Laser RFL- 300/3000

Raytools BW-240 welding head

Teyu Laser Cooling system CWFL-4000

Laser welding in medical technology

Laser welding is used to manufacture components of medical devices such as implants, surgical instruments and diagnostic equipment.

Most frequently selected configuration for Laser welding in medical technology

Raycus QCW Laser RFL- 150/1500

Raytools BW-240 welding head

Teyu Laser Cooling system CWFL-2000

Laser welding in the aerospace industry

Laser welding is used in the manufacture of aircraft structures from aluminum, titanium and other materials to create lightweight and durable components.

Most frequently selected configuration for Laser welding in the aerospace industry

Raycus CW Laser RFL- C6000H-CE

Raytools welding head BF330-6F

Teyu Laser Cooling system CWFL-6000

Let us advise you and test for yourself

If you have any questions, need a quote or would like to test a configuration in our technical center, please send us an e-mail or simply give us a call. We will answer you as quickly as possible.

Contact us

Address

Innotech Laser GmbH

Giesenheide 31

40724 Hilden

Germany

Office hours

Monday to Thursday

08:30 am to 5:00 pm

Friday

08:30 am to 4:00 pm

Further applications

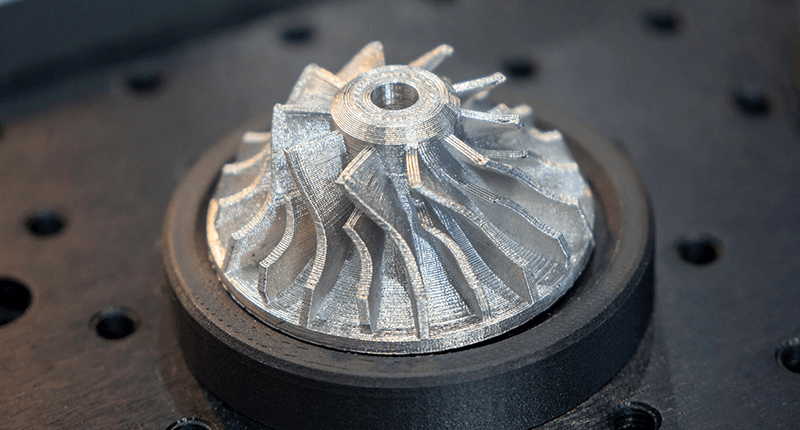

Laser 3D printing

Laser Additive manufacturing, or Laser-based 3D printing, is a revolutionary manufacturing technology for creating prototypes and sample parts.

Laser cleaning

The cleaning of surfaces with Laser technology offers numerous application possibilities in various industries.

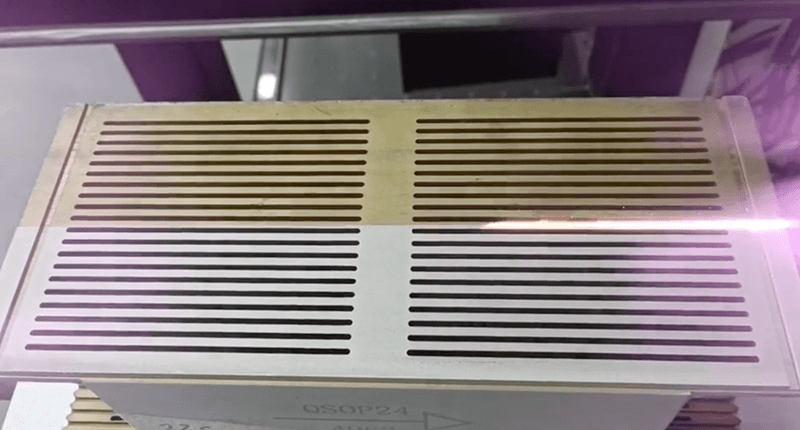

Laser cutting

Laser systems are tools that are low-wear and versatile. They are therefore used in almost all industries for cutting materials, hard or soft.

More about cutting Laser